Contact UsQuick Quote

We Manufacture Rotary Piston Positive Displacement Pumps

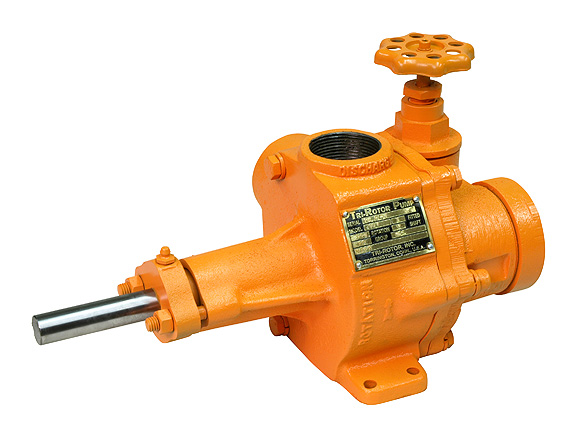

The Tri-Rotor pump is classified as a positive displacement (PD) pump like gear pumps, progressive cavity pumps, diaphragm pumps, and sliding vane pumps. Like other PD pumps, this pump has good vacuum characteristics, is self-priming, and produces a constant flow through each cycle of operation.

Any questions? Please Contact Us for some answers!

10 Points of Superiority for Tri-Rotor's Rotary Piston Positive Displacement Pumps

- Unique Tri-Rotor rotary piston pump principle

- Simplicity…only three moving parts

- Practically noiseless operation

- Extra-long bronze shaft bearing

- Oversized packing gland

- Minimum maintenance demonstrated in the field

- Will not chew, aerate, or foam the material pumped

- High volumetric efficiency on thin and viscous materials

- Continuous discharge pressure and a steady rate of flow

- Exceptionally long service life

Any questions? Please Contact Us for some answers!

Series 20 – Up to 30 GPM

Series 20CP Close Coupled – Up to 30 GPM

Series 40 – Up to 40 GPM

Series 80 – Up to 80 GPM

Series 100 – Up to 100 GPM

Series 120 – Up to 120 GPM

Series 200 – Up to 200 GPM

Series 220 – Up to 220 GPM

The Tri-Rotor Pumping Principle is a Superior One.

Tri-Rotor's rotary piston positive displacement pumps provide many benefits.Rotary Positive Displacement Action with True Piston Strokes

- Smooth discharge characteristics with minimum pulsation

- Extremely high volumetric efficiency, saving power

- Virtually no mechanical beating makes for successful pumping of liquids which are shear sensitive or degraded by the centrifugal gear or paddle agitation common in other pumps

- Highly viscous liquids are easily handled as well as a thin volatile material

- Self-priming and high suction lift capability

Large Areas of Contact Between Mating Parts

- Exceptionally long service life because of low unit pressures between the pumping members – exactly the opposite to the high unit pressures encountered in gear and other type pumps

- Large mating areas trap fluid into hydro-dynamic support, preventing metal to metal contact, and prolonging pump life

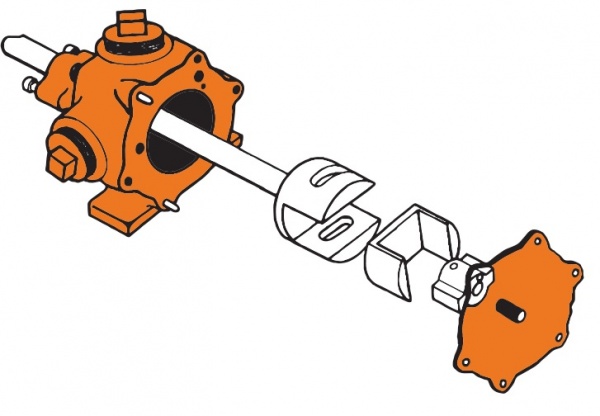

Only Three Pumping Members

- Maintenance-free operation, with practically no downtime

The Rotor (integral with the pump shaft) is slotted across its face. Two vents lead out from the slot sides to the rotor periphery. The rotor has a liquid-tight fit within the body bore and performs as a rotary valve, channeling the pumpage from the intake port around, within the casing and out the discharge port.

The Piston, which is U-shaped, fits liquid-tight in the rotor slot. As it slides back, the receding piston face draws liquid into the slot while passing the intake port of the pump, and traps a charge of fluid in the slot end. Then, revolving to the output side of the pump, the piston moves forward and pushes the trapped liquid out of the discharge port. The opposite face of the piston performs similarly at its end of the rotor slot, thus making the piston double-acting.

The Shuttle is a rectangular block nested in a liquid-tight fit inside the U of the piston. It slides back and forth within the piston, drawing liquid through one rotor vent while discharging through the opposite vent.

The Piston, which is U-shaped, fits liquid-tight in the rotor slot. As it slides back, the receding piston face draws liquid into the slot while passing the intake port of the pump, and traps a charge of fluid in the slot end. Then, revolving to the output side of the pump, the piston moves forward and pushes the trapped liquid out of the discharge port. The opposite face of the piston performs similarly at its end of the rotor slot, thus making the piston double-acting.

The Shuttle is a rectangular block nested in a liquid-tight fit inside the U of the piston. It slides back and forth within the piston, drawing liquid through one rotor vent while discharging through the opposite vent.